Frequently Asked Question - please read carefully to avoid errors.

The required information for a quote

To save some time, here are some prepared answers if you do not have a measurable size, design and usage in mind:

Q: "How much is a stamp?"

A: "Starting price is from about $150 each upwards depending on the complexity, size and material"

Q: "How long does it take for the stamp to be made?"

A: Depending on my workload stamps are usually finished within 3 to 4 weeks from the time I receive the payments.

Some stamps might take longer if I do not have the material in stock or there is extra complexity to manufacture it.

Be patient, good things are worth waiting for.

Q: "How much is a small (or large, or medium) stamp?"

A: I cannot quote without a measurable size and design image.

If you insist, then I guess the answer would be "most stamps can be made for under $2 million"

Q: What is the meaning of complexity?

A: The stamp for the letter "I" would be cheaper than letter "N", which in turn are cheaper than the letter "B"

The more turns, holes, and dead ends, the more complex the machining would be and the higher the cost would be.

Put it simply, the price of a stamp is dependent on its SIZE, design/machining COMPLEXITY and type of MATERIAL it is made of.

Please read the information in this page carefully - they are written to help you get exactly the correct product you wish to be made.

The information I need from you are as follows:

1. The image design of the logo preferably in VECTOR format encapsulated in PDF format.

This is one of the MOST important thing to ensure no confusion, as many version of software creates different vector files, saving to PDF would made it possible for the image to be opened with any PDF reader. If you are unable to supply vector file, then you can also send me a high resolution JPG or PNG file.

2. The exact size for the imprint you want to be in millimeter (give me how WIDE the whole design should be)

3. The work surface you wish for the stamp to be used on (leather, steel, gold, animal branding etc)

4. The method of application you wish to employ (hammering, pressing, branding etc)

5. Your material preference (aluminum, brass, tool steel etc)

6. Your delivery address for postage estimate.

I would not able to give you a quote without the required information above

Below are detailed explanation of what are required.

Please read the whole page carefully to eliminate possibility of confusion or errors in making your stamp.

Please note that I DO NOT offer logo drawing service, I cannot draw your logo for you because I do not have the facility to do that. There are a lot of graphic artist that can do the job - one that I recommend is Andrew Smith [email protected]

Size

When asking for a quote, please send me a standard measurable units, in centimeter, millimeter or inch.

Arbitrary units such as small, large, medium or your grandpa's big toe size is NOT usable.

Having said that, I found many customer like to have large stamps, but unfortunately have no means to provide enough force to press the stamp to give good imprint.

On steel, you would need at least 200 kg of pressure per each mm² of surface area to be able to imprint well.

On leather, roughly 500 kg per each square centimeter (100 mm²) are required.

I will make the stamp to the size as requested, you would have to ensure that the setup you have is adequate to provide the force, and the material you wish to stamp it with are able to absorb the stamping force.

Common Sizes

One of the more popular question is - "What is the size commonly used for XXXX"

Generally for a small knife (up to 6 inch) a good stamp size is what would fit within 8 to 12.5 mm diameter area

For a large knife, you could increase to 15 - 18mm diameter.

For blacksmithing touchmarks, usually clients would ask for 20 to 30 mm diameter stamps.

It is imperative to understand that the larger the stamp, the more force required to mark the steel and the more steel to be moved.

Leather makers stamps are generally fits within 25 to 40 mm diameter.

Branding irons are approximately the same as leather stamps

Jewelers stamps are usually 3 - 5 mm wide

In the past some client would say that they will leave the sizing to my expertise and experiences..

Sorry mate, you got to make up your own mind as to what size and how your logo would come out like.

Except for the trial imprint I have no experience whatsoever with YOUR logo stamp and thus am not qualified to make this decision for you. I can only make the stamp or stencils to the size as requested.

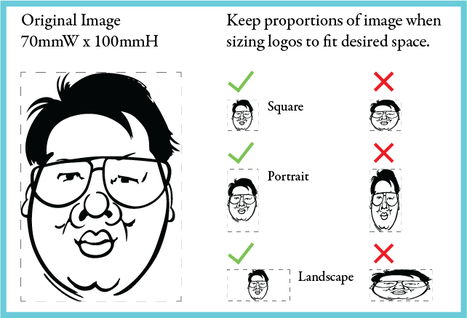

Proportional scaling

If you send me an image that have different proportional scale than the requested final size, you would have to tell me if you wish for the image to be stretched to fit or for me to fit the image within the bounding boundary.

If you want the image to fit within a certain size boundary, please tell me the bounding restrain, eg. if you want it to fit within 20 mm diameter or the overall width is to be 15 mm or the height to be 12 mm.

Telling me that you want a 12 mm stamp means nothing because it could be 12 mm diameter, width or height and will not usually be what you wanted.

Design Complexity

The main thing that determine the pricing of a job is how complex the design looks.

The more difficult it is to machine the more expensive it is to be produced.

The rule of thumb in designs is - Keep it simple.

Remember the more complex and high detailed your design is, the higher the price it is to make.

Thus the reason why I cannot quote without seeing the design.

Please send your image when asking for a quote.

Material

Currently I can make stamps out of (in order of soft to hard)

The harder material will last longer and cost more to make.

Purpose

Price of stamps made for leather, steel or branding varies greatly.

Again unless I know what you wish to use the stamps for, it would be difficult for me to give you a quote.

Method of application

Different person would utilise different method of application, some prefer hammering and others might use press.

If you do not tell me what method you are using I would assume you would be hammering the stamp and thus will make the stamp to the shape that is suitable for hammering. If this is not what you wanted, please tell me your preference when you order.

Q: "How much is a stamp?"

A: "Starting price is from about $150 each upwards depending on the complexity, size and material"

Q: "How long does it take for the stamp to be made?"

A: Depending on my workload stamps are usually finished within 3 to 4 weeks from the time I receive the payments.

Some stamps might take longer if I do not have the material in stock or there is extra complexity to manufacture it.

Be patient, good things are worth waiting for.

Q: "How much is a small (or large, or medium) stamp?"

A: I cannot quote without a measurable size and design image.

If you insist, then I guess the answer would be "most stamps can be made for under $2 million"

Q: What is the meaning of complexity?

A: The stamp for the letter "I" would be cheaper than letter "N", which in turn are cheaper than the letter "B"

The more turns, holes, and dead ends, the more complex the machining would be and the higher the cost would be.

Put it simply, the price of a stamp is dependent on its SIZE, design/machining COMPLEXITY and type of MATERIAL it is made of.

Please read the information in this page carefully - they are written to help you get exactly the correct product you wish to be made.

The information I need from you are as follows:

1. The image design of the logo preferably in VECTOR format encapsulated in PDF format.

This is one of the MOST important thing to ensure no confusion, as many version of software creates different vector files, saving to PDF would made it possible for the image to be opened with any PDF reader. If you are unable to supply vector file, then you can also send me a high resolution JPG or PNG file.

2. The exact size for the imprint you want to be in millimeter (give me how WIDE the whole design should be)

3. The work surface you wish for the stamp to be used on (leather, steel, gold, animal branding etc)

4. The method of application you wish to employ (hammering, pressing, branding etc)

5. Your material preference (aluminum, brass, tool steel etc)

6. Your delivery address for postage estimate.

I would not able to give you a quote without the required information above

Below are detailed explanation of what are required.

Please read the whole page carefully to eliminate possibility of confusion or errors in making your stamp.

Please note that I DO NOT offer logo drawing service, I cannot draw your logo for you because I do not have the facility to do that. There are a lot of graphic artist that can do the job - one that I recommend is Andrew Smith [email protected]

Size

When asking for a quote, please send me a standard measurable units, in centimeter, millimeter or inch.

Arbitrary units such as small, large, medium or your grandpa's big toe size is NOT usable.

Having said that, I found many customer like to have large stamps, but unfortunately have no means to provide enough force to press the stamp to give good imprint.

On steel, you would need at least 200 kg of pressure per each mm² of surface area to be able to imprint well.

On leather, roughly 500 kg per each square centimeter (100 mm²) are required.

I will make the stamp to the size as requested, you would have to ensure that the setup you have is adequate to provide the force, and the material you wish to stamp it with are able to absorb the stamping force.

Common Sizes

One of the more popular question is - "What is the size commonly used for XXXX"

Generally for a small knife (up to 6 inch) a good stamp size is what would fit within 8 to 12.5 mm diameter area

For a large knife, you could increase to 15 - 18mm diameter.

For blacksmithing touchmarks, usually clients would ask for 20 to 30 mm diameter stamps.

It is imperative to understand that the larger the stamp, the more force required to mark the steel and the more steel to be moved.

Leather makers stamps are generally fits within 25 to 40 mm diameter.

Branding irons are approximately the same as leather stamps

Jewelers stamps are usually 3 - 5 mm wide

In the past some client would say that they will leave the sizing to my expertise and experiences..

Sorry mate, you got to make up your own mind as to what size and how your logo would come out like.

Except for the trial imprint I have no experience whatsoever with YOUR logo stamp and thus am not qualified to make this decision for you. I can only make the stamp or stencils to the size as requested.

Proportional scaling

If you send me an image that have different proportional scale than the requested final size, you would have to tell me if you wish for the image to be stretched to fit or for me to fit the image within the bounding boundary.

If you want the image to fit within a certain size boundary, please tell me the bounding restrain, eg. if you want it to fit within 20 mm diameter or the overall width is to be 15 mm or the height to be 12 mm.

Telling me that you want a 12 mm stamp means nothing because it could be 12 mm diameter, width or height and will not usually be what you wanted.

Design Complexity

The main thing that determine the pricing of a job is how complex the design looks.

The more difficult it is to machine the more expensive it is to be produced.

The rule of thumb in designs is - Keep it simple.

Remember the more complex and high detailed your design is, the higher the price it is to make.

Thus the reason why I cannot quote without seeing the design.

Please send your image when asking for a quote.

Material

Currently I can make stamps out of (in order of soft to hard)

- Magnesium (softest material I use for leather stamps or heat foil transfer stamps)

- Aluminum (main material used for leather stamps and wax seals)

- Brass (good for branding or leather stamping)

- Grade 3XX Stainless steel (usually used for food branding or production scale leather stamping)

- H-13 hot work tool steel (usually at 50-52 HRC generally used for blacksmithing and hot stamping)

- D2 Cold work tool steel (hardest material at 55-58 HRC for stamping on cold spheroidally annealed steel)

The harder material will last longer and cost more to make.

Purpose

Price of stamps made for leather, steel or branding varies greatly.

Again unless I know what you wish to use the stamps for, it would be difficult for me to give you a quote.

Method of application

Different person would utilise different method of application, some prefer hammering and others might use press.

If you do not tell me what method you are using I would assume you would be hammering the stamp and thus will make the stamp to the shape that is suitable for hammering. If this is not what you wanted, please tell me your preference when you order.

Image requirements to order a stamp, touchmark or stencil

NEVER send actual size artwork, they are almost always not good enough for stamp or stencil making.

Always send larger size artwork and I will scale it down to your requirement.

Always send the image the way you want the imprint to look like, NEVER SEND MIRRORED Image.

Redrawing fees will be added if image supplies is not suitable for production.

1. Resolution requirement.

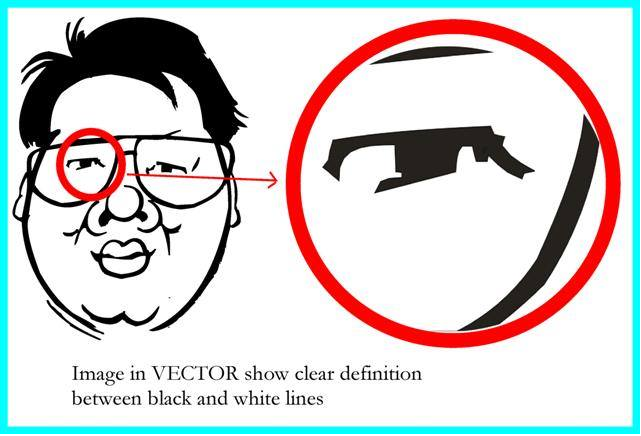

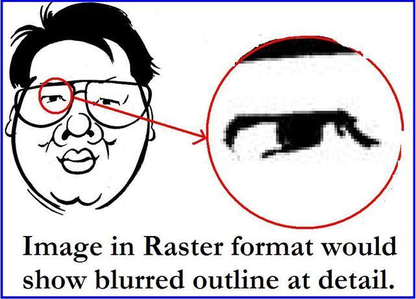

It is best to supply your image in VECTOR format such as SVG, DXF, CDR or AI - encapsulated in a PDF.

Although it is possible to extract useful details from RASTER format such as jpg bmp or gif images, they are essentially a grey scale and thus do not have clear definition between black and white lines.

While either vector or raster format might show up fine on your screen, there are fundamental differences that really determine the final result.

If you are unable to provide vector image, please send your image as a large HIGH RESOLUTION - BLACK and WHITE (monochrome only) at least of 300 dot per inch (DPI) so fine details could be extracted. Please ensure that you do not send me large empty page with small design in there somewhere (this would be quite useless).

The best way to see if your image is good is to enlarge the image to full size on your computer screen, if the edges of the image shows up blurry then most of the time it would not be good enough. On the other hand, high resolution raster images usually show up with very little blurriness and thus acceptable for the data extraction.

I find that FREEWARE vector drawing program such as Inkscape works very well in drawing logos. If you do use INKSCAPE then please send me the image as PDF.

Redrawing fees will be added if image supplies is not suitable for production.

Always send larger size artwork and I will scale it down to your requirement.

Always send the image the way you want the imprint to look like, NEVER SEND MIRRORED Image.

Redrawing fees will be added if image supplies is not suitable for production.

1. Resolution requirement.

It is best to supply your image in VECTOR format such as SVG, DXF, CDR or AI - encapsulated in a PDF.

Although it is possible to extract useful details from RASTER format such as jpg bmp or gif images, they are essentially a grey scale and thus do not have clear definition between black and white lines.

While either vector or raster format might show up fine on your screen, there are fundamental differences that really determine the final result.

If you are unable to provide vector image, please send your image as a large HIGH RESOLUTION - BLACK and WHITE (monochrome only) at least of 300 dot per inch (DPI) so fine details could be extracted. Please ensure that you do not send me large empty page with small design in there somewhere (this would be quite useless).

The best way to see if your image is good is to enlarge the image to full size on your computer screen, if the edges of the image shows up blurry then most of the time it would not be good enough. On the other hand, high resolution raster images usually show up with very little blurriness and thus acceptable for the data extraction.

I find that FREEWARE vector drawing program such as Inkscape works very well in drawing logos. If you do use INKSCAPE then please send me the image as PDF.

Redrawing fees will be added if image supplies is not suitable for production.

2. Colour and grey scales tone

All image submitted should be in MONOCHROME (BLACK and WHITE with no grey color)

There is no actual color, grey scale or half tone on etching or stamping, like news print all half tone are simulated by varying the size of dots on the print itself, half tone on etching or stamping could be simulated with varying the thickness of your lines. But although this is possible, on the actual manufacturing of the stamp or stencil very fine lines may disappear altogether and the end result may not be as what you think it would be.

I strongly discourage the use of grey scales or half tone in the designs.

If you really want to do half tone, you would need to vectorize your image and you would be responsible for all the costs of production even if the design do not turn out the way you want them to be.

3. Fine details

While it is possible to manufacture stamps or stencils down to about 0.1mm lines, it is not recommended to design lines that are thinner than 0.5 mm. On Leather stamps, any lines thinner than 0.5mm would CUT the leather rather than compressing it. On Stencils, lines thinner than 0.5mm might not have enough clearances for the electrolyte to pass through thus the result of the etch may be blotchy.

Fine details or character on touchmarks down to 1 mm is possible to be machined, however these would be considered as jewelry stamp grade and this will be EXPENSIVE.

They are good for soft metal such as gold and silver, but will not show up well on steel due to the limit of the flow of the steel.

Cost for jewelry grade stamps would be MUCH higher than of normal steel stamps due to the complexity of high precision machining required.

My suggestion for characters for steel stamps/touchmarks not to be smaller than 2.5 mm tall to ensure good imprint and long life for your stamps.

4. Fonts

Often fancy fonts are designed into the design, this are Ok, but it would be best to include the TTF file (the actual font files) when you are using fonts that are not native on Windows or Mac. This is to ensure that we could replicate your design properly on the stamps or stencils.

On steel touchmarks fancier fonts would increase the complexity of the machining greatly.

5. Photos

Unless the photo is clear image of the logo and in black color and pure white background, the chance of extracting data from the photo is exactly zero, so NEVER SEND PHOTO of your logo.

Having said the above, I could always help you in producing your logo image for good result in stamping and stencils. This service will provided with a cost, depending on your requirements, the cost will vary from a minimum of $100 to $500 for difficult designs. Time point for design service would vary depending on complexity of the design. The design will be done by outsource, I do not do the design for you, I will send the job out to graphic artist and this will take longer time to be done.

Redrawing fees will be added if image supplies is not suitable for production.

6. Always send the image the way you want the imprint to look like, NEVER SEND MIRRORED IMAGE.

If you sent me a mirrored image then you will be charged for the full price again to re make correctly oriented stamp.

Postage and Payments

Postage

Yes I can and do post my product overseas,

My usual method of delivery is either via Australian Post and the estimated postage rate can be found >> here <<,

I would insist on Tracking, and Insurance would be an option to be purchased to ensure peace of mind between you and me.

All orders will be posted with tracking number or tracking links.

PLEASE include your postal address when contacting me for a quote,

I need to estimate the posting cost to send the product to you.

Payment methods

Payment for Overseas orders can be made with either Paypal or Telegraphic Transfer.

Cost for the telegraphic transfer (AU$20) or paypal (7%) payment will be added on top of the quoted price..

All Australian orders need to be paid by Direct Deposit to my bank account.

On both instances, no item will be posted or made before the payment is cleared into my account.

Yes I can and do post my product overseas,

My usual method of delivery is either via Australian Post and the estimated postage rate can be found >> here <<,

I would insist on Tracking, and Insurance would be an option to be purchased to ensure peace of mind between you and me.

All orders will be posted with tracking number or tracking links.

PLEASE include your postal address when contacting me for a quote,

I need to estimate the posting cost to send the product to you.

Payment methods

Payment for Overseas orders can be made with either Paypal or Telegraphic Transfer.

Cost for the telegraphic transfer (AU$20) or paypal (7%) payment will be added on top of the quoted price..

All Australian orders need to be paid by Direct Deposit to my bank account.

On both instances, no item will be posted or made before the payment is cleared into my account.

Warranty

As in any product made and sold in Australia, you are covered with 12 months warranty for defects due to mistake done in manufacturing.

This warranty does not cover misuse such as stamping on harder material than what the stamp is designed for, thermal shocks, heat tempering of touchmarks, over pressuring, stressed and other causes.

Costs to return the defective item to me is the responsibility of the buyer..

Check and Recheck the logo you sent to me.

Custom work once ordered are not changeable, cannot be cancelled and cannot be refunded.

This warranty does not cover misuse such as stamping on harder material than what the stamp is designed for, thermal shocks, heat tempering of touchmarks, over pressuring, stressed and other causes.

Costs to return the defective item to me is the responsibility of the buyer..

Check and Recheck the logo you sent to me.

Custom work once ordered are not changeable, cannot be cancelled and cannot be refunded.